Our security fencing products

Rotary Spike 230 mm Hot Dip Galvanised Steel

Designed to prevent climbing by removing grip at the top of the fence. The 230 mm tube rotates under

pressure. Installed on 42 mm round rails. Galvanised coating protects against corrosion in permanent

outdoor setups. Applied on perimeter lines where physical deterrence is critical.

Rotary Spike 120 mm Hot Dip Galvanised Steel

Three welded points, each 120 mm long, fixed to a pressed metal sleeve. Slides directly over a 42 mm

top tube. A rigid barrier with moving parts. Increases visual and physical resistance without adjusting

the main fence structure.

Rotary Spike 90 mm Hot Dip Galvanised Steel

Smaller variant with three welded tips of 90 mm. Built for lighter fence lines that still require clear

separation. Pressed metal body fits 42 mm round tubes. Reinforces the top edge with a sharp, compact

deterrent.

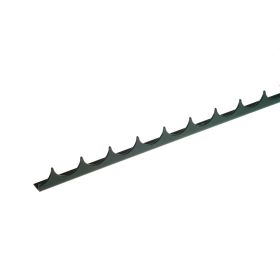

Threaded Spike Bar 1000 mm Hot Dip Galvanised Steel

One metre long anti climb bar with fixed spike profile. Threaded for mounting onto clamps or post

caps. Hot dip galvanised for outdoor use. The straight layout reinforces the top edge without adding

moving elements.

Threaded Spike Bar 2000 mm Hot Dip Galvanised Steel

Two metre bar for uninterrupted perimeter protection. Spike profile welded across the full length.

Threaded ends ensure a secure mechanical connection. Extended spans can be secured without

interruption or drop in height.

Hexagonal Nut M8 Stainless Steel 304

Standard fastening nut for steel fence components. M8 size for structural connections across clamps,

brackets and post assemblies. Stainless steel 304 resists corrosion and mechanical wear in exposed

environments. Torque is maintained under pressure, even in high-vibration settings.

Lock Nut M8 DIN 985 Stainless Steel 304

Self-locking nut with integrated nylon insert. Prevents loosening under vibration or mechanical stress.

DIN 985 compliant. Designed for M8 thread applications within fixed or dynamic fencing structures.

Stainless steel 304 body for long-term durability outdoors or in chemically aggressive zones.

What is Security Fencing?

A permanent fencing system used to regulate access, separate functional zones and block

unauthorised movement on exposed or high risk sites. The build aligns with site pressure, connection

method and terrain layout, ensuring each section holds position and absorbs force without shifting.

Where general fencing defines a border, this solution acts as a physical barrier that stops movement

and integrates with access points, visible deterrents and fixed closures. Placement is based on how the

site operates. Vehicle flow, foot traffic and peak loads determine where reinforcement is required.

Design choices depend on exposure, mounting type and spatial complexity. Every component is

selected for function, visibility and deterrent strength. The result is a fence that holds under pressure,

absorbs impact and enforces access control through a system that stays in position.

Commercial or Residential Security Fencing?

Security fencing functions differently based on location and purpose. In low-risk environments, the

structure marks spatial boundaries and supports site organisation. In high-risk or restricted zones,

fencing is installed to block access, absorb impact and enforce controlled movement. On exposed or

restricted ground, the construction must block access, absorb force and support site control. How each

section connects, how the weight is distributed and how the fencing supports daily movement define

how the system performs in position.

Commercial security fencing is placed around compounds, machinery zones and high-value storage

where physical separation must be guaranteed. Metal configurations span wide surfaces. Sections are

heavier, anchored with base plates or embedded directly into concrete. Fence lines run uninterrupted,

including around gates. The upper edge may include barbed profiles or rotating spike bars to limit

climbing. All parts are selected to hold weight, resist pressure and function without distortion across

multiple use cycles.

Residential fencing creates boundary lines without obstructing movement. Layouts follow garden

edges, driveways or shared borders. Heights are lower, components lighter and installation points

designed for simple adjustment. The structure supports clarity and separation, not complete

restriction. Anti climb elements are rarely included.

Benefits of Metal Security Fencing?

Metal fencing is designed to resist mechanical stress, shifting terrain and prolonged weather exposure.

Galvanised steel preserves structural integrity across decades, performing without correction or

replacement. In high‐pressure environments, the framework remains aligned under vibration, impact

and continuous use. Surface coatings prevent wear and corrosion, minimising material waste and

reducing the need for replacement parts. The core structure remains untouched, resulting in low

maintenance and efficient material use.

Deterrent components reinforce this setup without affecting structural reliability. Spike bars form a

fixed barrier at the top edge, blocking climbing attempts. Rotary profiles disrupt grip by rotating under

contact. Barbed wire arms extend the upper line outward, increasing visual and physical separation

without compromising the base frame. Once mounted, every panel holds alignment, absorbs force and

resists movement under continuous use. Each attachment is fixed with lock nuts, brackets and post

caps that maintain mechanical stability without adjustment.

Custom Solutions for Unique Requirements

Security fencing is rarely one-size-fits-all. Locations with critical infrastructure, cross-border transport

or protected wildlife zones demand precise solutions that align with environmental, operational and

regulatory constraints. These requirements go beyond standard dimensions or fixed layouts. Each site

must be assessed for risk exposure, traffic direction and long-term durability.

Buisklem components are configured to meet these parameters without altering core stability. Custom

solutions are not redesigns, but refinements. Adjustments are made for slope, height variation or

obstacle bypass, while retaining alignment, tension and performance. The layout reflects the terrain

and access logic of the site, not the limits of prefabricated panels.

From remote installations to urban infrastructure corridors, Buisklem delivers fencing that meets

unique demands. Each project starts from known mechanical principles and ends in an application that

maintains integrity under pressure, season after season.

Buisklem Supplies Security Fencing Solutions Across Europe

Buisklem provides modular metal security fencing systems to installers, distributors and project

managers throughout Europe. Both standard and custom configurations are held in stock for

immediate shipment, supporting urgent tasks and complex site requirements. Each component is

engineered for structural integrity, access control and long-term durability. Parts are rigorously tested

before shipping to ensure mechanical alignment and finish. On-site installation guidance ensures

proper placement and performance from the first fit. Buisklem combines consistent inventory,

technical expertise and product reliability to safeguard infrastructure zones, operational perimeters

and high-risk environments across the region.