Steel Tube Connector Range

The right connector determines how a frame performs over time. The range of steel tube components includes solutions for every structural requirement: load transfer, tube alignment, joint stability and long-term resistance to movement.

1. T-Clamp (2-Part), hot-dip galvanised

Two-part steel fitting for round tube intersections in construction and fencing systems, secured with

set screws and finished with a hot-dip zinc coating for durable outdoor use.

2. T-Clamp (2-Part) with lip, hot-dip galvanised

Two-part steel fitting with internal stop for fixed 90° tube joints, used in agricultural frames and

livestock housing, and finished with a hot-dip zinc coating for durable outdoor use.

3. T-Clamp (2-Part) with lip, heavy, hot-dip galvanised

Two-part steel fitting with internal stop for 90° tube joints, used in livestock housing and agricultural

frameworks, and finished with a hot-dip zinc coating for long-term outdoor performance.

4. T-Clamp (One-Part), hot-dip galvanised

Compact steel fitting for 90° tube connections in lightweight structures, secured with pre-installed bolt

and nut, and protected with a hot-dip zinc coating for use in fencing and frames.

5. Cross-Joint (2-Bolt), hot-dip galvanised

Steel fitting for straight tube intersections in structural layouts, secured with two opposing set screws

and finished with a hot-dip zinc coating for reliable use in fencing and modular systems.

6. Cross-Joint (2-Bolt) heavy, hot-dip galvanised

Reinforced steel fitting for structural cross-connections in round tube assemblies, secured with twin

set screws and finished with a hot-dip zinc coating for long-term use in fencing systems and high-load

constructions.

7. Cross-Joint (4-Bolt), hot-dip galvanised

Heavy-duty connector for four-way tube intersections in structural grids, secured with four set screws

and finished with a hot-dip zinc coating for high-load agricultural and fencing systems.

8. Pipe Connecting Clamp (One-Part), hot-dip galvanised

Compact steel fitting for inline tube joints, secured with internal set screws and finished with a hot-dip

zinc coating for use in static frameworks, railings and modular systems.

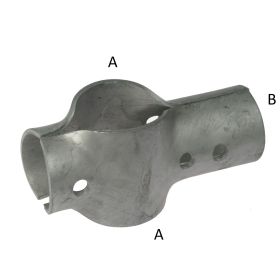

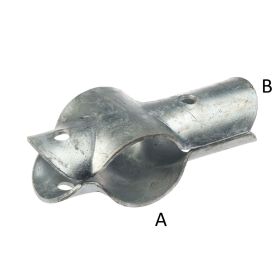

9. Split Tube Connector, hot-dip galvanised

Two-part steel fitting for straight tube joints in modular or extended assemblies, clamped externally

and hot-dip galvanised for structural use in fencing, repairs and stable systems.

10. Steel Pipe Connector, hot-dip galvanised

Straight sleeve fitting for joining round steel tubes in static assemblies, installed without welding and

protected by a hot-dip zinc coating for use in fencing, construction and technical installations.

11. Tube Connector (Internal), hot-dip galvanised

Internal steel sleeve for hidden tube joints, pressed into place without tools and finished with a hot-

dip zinc coating for clean inline connections in railings, frames and steel systems.

What Are Steel Tube Connectors?

In modular steel tube construction, mechanical fittings define how loads are distributed, aligned and fixed across a structure. The connectors provide fixed geometry points where tubes intersect, turn or terminate. Individual fittings determine how the structure reacts at that junction: locking movement, resisting torsion or guiding direction. Rather than relying on welded joints, the components uses mechanical pressure from a single set screw to clamp tubes in place without deformation. This allows adjustments during installation, controlled tensioning and precise positioning. Fittings include T joints for perpendicular connections, cross joints for multi-direction intersections, elbows for angled changes and base plates to secure uprights. Internal sleeves are used where inline reinforcement is required without visible overlap. Components are installed using a hex key and designed to match standard tube diameters for example 26.9 and 33.7 millimetres. The modular format ensures that each connection type can be reused across identical layouts without customisation. Tube connectors make it possible to create repeatable structures that maintain rigidity while remaining serviceable. Whether used in technical enclosures, mobile units or agricultural assemblies, the system standardises construction without limiting flexibility.

Choosing the Right Steel Tube Connector

Connector selection depends on three main factors: matching the correct tube diameter, identifying the connection type and assessing whether the structure is for indoor or outdoor use. Standard options include two way, three way and swivel connectors, each suited to specific frame configurations.

- Two way connectors join two tubes, either straight or at a right angle. Used in simple frames

and fixed constructions where a rigid connection between two parts is required and no

movement is expected.

- Three way connectors join three tubes, often forming T or cross shapes. Used in more complex

layouts where multiple directional forces need to be absorbed. The third connection point

increases structural integrity and improves frame stability.

- Swivel connectors allow controlled rotation between tubes. Used in adjustable structures or

mobile elements that require flexibility without compromising joint strength. The connection

maintains mechanical stability while enabling angular movement.

For outdoor applications, use corrosion-resistant materials such as galvanised steel. Fixing rails add extra support and stabilise the structure without needing major changes.

Benefits of Zinc Coated and Hot Dip Galvanised Steel Tube Connectors

Zinc coated steel connectors offer reliable, low-maintenance performance in exposed structural applications. The protective zinc layer is applied through hot dip galvanising, where each connector is immersed in molten zinc to form a dense, weather-resistant barrier. This coating shields the underlying steel from moisture, chemical exposure and temperature fluctuation, significantly extending service life. The finish allows use in agricultural constructions, production environments, coastal installations and areas where hygiene or climate conditions demand consistent material performance. Zinc coated tube connectors combine mechanical strength with lasting corrosion resistance.

Quick Installation Tips

Successful installation starts with selecting the correct tube diameter and making sure all contact surfaces are clean and dry. Contamination from oil, dust or corrosion reduces grip and can lead to slipping or misalignment. Torque wrenches, spanners and hex keys allow precise tightening without damaging the connector or distorting the tube. Screws should be tightened until the tube is held firmly, without applying excessive force. Overtightening risks thread damage and weakens the connection. Begin with the main framework to set alignment and distribute load before fitting additional parts. This prevents shifting during assembly, especially in larger or heavier constructions. After mounting, check all joints for position, tension and stability. A final check confirms that everything is secure and ready for use. Finish installation by fitting plastic caps on all tube ends to prevent dirt and moisture from entering.

Buisklem Supplies Steel Tube Connectors for Construction and Technical Projects Across Europe

Buisklem delivers hot-dip galvanised steel tube connectors to installers and distributors throughout Europe. Products are kept on hand in large volumes for immediate shipment, so urgent requests and ongoing projects are always covered. Technical help is available for both installation and selection, ensuring every project has the right connector without delay. All standard tube diameters are supported, with connectors tested for fit and finish before dispatch. Orders are tracked from warehouse to job site, providing professionals with full oversight of supply and delivery. Buisklem combines reliable stock, practical support, and consistent quality for modular construction projects across the region.