What Defines an Optimal Stable Setup?

A well-structured livestock facility gives farmers complete control over animal flow and space

allocation. Animals move calmly through feed alleys and holding areas, without abrupt turns or blocked

paths. The setup adapts to changing herd conditions, from calf separation and quarantine zones to pen

reconfigurations after calving. Surfaces are smooth, dirt resistant and easy to clean with pressure

systems, without dismantling. For stable builders,

components align without modification, install

cleanly and fit existing plans. A setup that speeds up daily routines, simplifies installation and holds up

under continuous use delivers real value on the farm.

Stable Equipment for Cattle, Goats, Sheep and Horses

Durable fittings and connection elements are

essential for building safe, functional stables. Steel

clamps, cross-connectors and pipe brackets form the core of pen walls,

feed lanes and holding gates.

For cattle, high-torque hinges and bolt-secured feed barriers ensure safe handling under load. Sheep

and goats benefit from lightweight separation panels and corrosion-proof brackets for open layouts.

Horses require rounded components such as ring clamps and smooth wall mounts to avoid impact

injuries. Each product is hot-dip galvanised and designed for repeated installation without on-site

modification. From gate locks to board holders, all hardware fits standard steel tube profiles used

across agricultural housing. The full range is suitable for indoor and outdoor setups and supports

reliable, hygienic animal control across seasons.

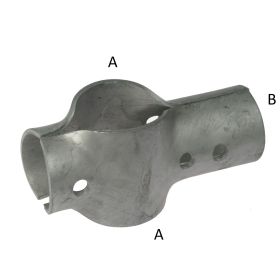

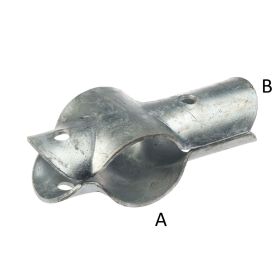

Tube Clamps and Structural Fittings for Stall Partitions

Barriers in livestock housing control movement between feeding, resting and holding zones.

Galvanised tubes connect with bracket clamps and corner braces, locking panels in

place without

welding. Cross-connectors support

multi-directional layouts for pens or calf enclosures. Floor brackets

and wall-mounted supports stabilise

pressure points in narrow walkways. Each part is fitted on site,

using only hand tools, and aligns with standard tube dimensions. Quick repositioning is possible when

herd sizes change or cleaning is required.

Clamp Fittings for Feed Access and Animal Restraint

Specialised couplers are used to build adjustable

feeding gates, neck restraints and control points that

improve comfort for livestock and reduce handling stress. Components can be configured to match

animal height and body width, ensuring safe access without injury. The fittings are often installed at

headlocks, entry points or side rails to keep animals calm and handlers protected.

Planning a Stable Setup with the Right Equipment and Layout

Successful stable planning begins with analysing the herd size, animal type and operational workflow.

Layouts are mapped by identifying feeding zones, resting areas and walking paths. Structural

requirements such as tube dimensions, clamp points and pressure zones are calculated to match

animal weight and behaviour. Once the zones are set, components like barriers, headlocks and

mounting plates are selected based on durability, hygiene and adjustment range. Assembly planning

includes the order of installation, anchoring methods and access for tools. A complete checklist

ensures no fitting or connection point is overlooked. Proper planning reduces installation time,

improves animal handling and avoids costly changes later on.

Durable Stable Equipment Made from Galvanised Steel

Stable fittings are constantly exposed to moisture, impact and livestock contact. To ensure consistent

performance, all pipe couplers, clamps and mounting elements are produced from hot-dip galvanised

steel. The zinc layer forms a corrosion-resistant barrier across all surfaces, including internal threads

and contact points. Even in demanding conditions such as high humidity or manure exposure, the

material resists wear and preserves its structural grip. Choosing durable components reduces

maintenance, prevents failure and extends the service life of the stable setup. Long-lasting materials

support animal welfare, reduce waste and add long-term value to every livestock facility.