What Are Barbed Wire Brackets?

Barbed wire holders secure multiple strands above a fence or wall where climbing must be physically blocked. Each bracket places the wire at an outward angle, increasing the vertical reach and reducing grip points along the structure. Once mounted, the upper line forms a continuous obstacle that resists pressure and absorbs impact without deformation. Common use includes fencing for logistics hubs, detention areas, sporting facilities and restricted industrial sites. The angled arms make overhead access visibly harder and delay intrusion attempts by force. No adjustment is required after installation. Brackets remain under constant tension without regular maintenance or manual realignment.

Our Different Types of Barbed Wire Holders

Straight Bracket

Straight brackets (0°) guide barbed wire in a fixed line above the post, without angle or lateral shift. Each arm supports two or three strands with consistent spacing and reliable anchoring. This setup is used on long, straight sections of perimeter fencing where direction remains unchanged. Installations include solar parks, correctional facilities, data centres and sports grounds where straight alignment and wire tension must be maintained over the full span.

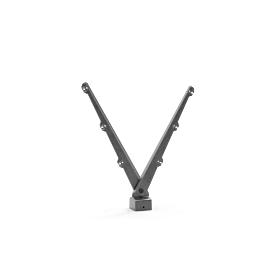

45-Degree Barbed Wire Brackets

A 45° bracket holds the wire away from the fence line, closing off access where direction changes or elevation increases. The angled setup extends surface coverage and eliminates hand contact at the upper edge. Each model carries two or three strands and is available with a single or double arm, depending on the site layout. Installation is typical around stepped fence lines at public venues, angled boundaries of correctional zones or raised sections in multi-level storage areas. Once mounted, the wire path remains stable without requiring later adjustment.

60-Degree Barbed Wire Brackets

A barbed wire arm set at 60° pushes the strands further outward, forming a steep angle that reduces climbing points and lowers the chance of contact near the fence top. The bracket supports two or three wires in a fixed offset that is often used where vertical clearance is limited or intrusion pressure is high. Installers choose this type for inner security lines, blind spots in compound layouts or perimeter sections with restricted access control. Each holder is available with a single or double arm and keeps wire tension stable without correction.

This Is How You Install a Barbed Wire Holders

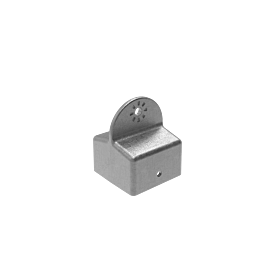

Position the barbed wire bracket level on the post head and aligned with the fence line before fastening. Pre-drilled holes accept hex screws or anchor bolts without adaptation. For steel or concrete posts, use galvanised or stainless fixings to avoid shear, corrosion or tension loss over time. Brackets must be placed on clean, flat surfaces and fixed without excessive force. Recommended spacing is 2.0 to 2.5 metres between brackets, depending on the wire setup and overall fence layout. Any deviation affects alignment and increases strain on the top section. Mounting errors at this stage lead to wire slack, unstable tension and visible deflection across the upper line.

Buisklem Is Europe’s Specialist Supplier of Barbed Wire Brackets

Wire brackets are developed to meet structural and safety requirements in perimeter fencing across industrial, agricultural and secured zones. Every model is tested for dimensional accuracy, load capacity and tension stability under long-term use. Standard formats are held in stock for immediate supply, while custom angles, coatings and configurations are produced to specification. Manufacturing and logistics are fully managed in-house, ensuring consistent fit, controlled output and reliable delivery. Professional installers and project engineers rely on these components for secure placement, repeatable alignment and zero deviation during mounting.