Pipe Couplers in Standard Sizes and Custom Variants

Pipe couplers available in standard sizes, from 26.9 millimetres to 60.3 millimetres, simplify installations for contractors and engineers across industries. Standardised dimensions ensure quick

assembly of handrails, industrial barriers, shelving systems, or structural supports without unnecessary delays or costly modifications. Standard pipe couplers are used in steel construction, farm enclosures, fencing systems and modular assemblies. Selecting standard couplers reduces procurement time, streamlines on-site workflows, and prevents compatibility errors.

Custom pipe couplers address specialised project requirements involving unique pipe dimensions, unusual angles, or specific load-bearing conditions. Bespoke couplers precisely match non-standard pipe configurations, eliminating the need for complicated on-site adjustments. Each fitting is machined to project specification and tested for consistent structural performance. Custom fabrication helps contractors complete complex or architecturally demanding installations smoothly, efficiently, and

safely.

A complete set of pipe couplers is available for fixed joints, angled layouts and oversized tubeconfigurations. Each fitting is specified based on pipe diameter, connection geometry and load behaviour. Repeat installations are completed without rework, even in variable site conditions or non-

standard assemblies.

Galvanised Cast Iron Pipe Couplers

Malleable cast iron is chosen for its ability to absorb force without cracking or distorting threads. Internal geometry remains stable under repeated torque, with no deformation across batches. Casting is done in steel moulds to hold fixed tolerances for wall thickness, diameter and thread pitch.

The zinc layer is applied through full hot-dip galvanisation. Threads, edges and internal contact points are immersed in a single process. No post-treatment is required, as full coverage is achieved during immersion. The coating resists corrosion, friction and contact with concrete dust or alkaline residue.

Fit and finish are verified at multiple points. Raw material, thread formation and coating depth are tested against internal tolerances. Components meet European Norm (EN) standards for structural connectors in steel assembly. Fittings seat without resistance and hold firm under load, even in frequent disassembly or exposed site conditions.

Types of Pipe Connection Elements and Clamp Configurations

Connection methods vary based on how the clamp secures the tube. Some designs apply full-sleeve pressure, while others rely on a single set screw to fix the joint. Hinged variants wrap around the pipe and close with bolts, distributing force across the contact area. Two-part models allow retrofitting when pipework is already in place. Fixed clamps may include internal stops that block rotation. Each variant serves a different structural purpose, from vibration resistance to static load bearing. Proper selection depends on torque, mounting position and contact surface. All factors matter in modular steel installations.

Fixed Single-Direction Couplers

Single-direction coupler holds the tube in a straight line using internal pressure or end-stop resistance. The fitting slides into or around the pipe and secures with a single set screw. Common types include inline joiners, end caps and locking inserts. Each piece blocks axial movement while keeping the pipe flush to the structure. Used in guardrails, straight runs or end terminations where clean alignment and static strength are required without full access to both sides.

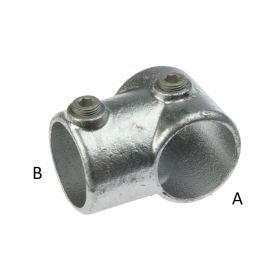

Multi-Directional Rigid Connectors

Rigid couplers link two to four tubes at fixed angles using bolt-fastened collars or opposing set screws. The connection resists movement in every direction and holds alignment without torsion or shift. Elbows, crosses and T-fittings are used in railing systems, framed supports and prefabricated assemblies. Each fitting grips the pipe with full contact and absorbs both static and dynamic load. The joint stays fixed under tension, surface pressure and repeated mechanical stress during installation

and use.

Swivel and Adjustable Clamps

Adjustable clamps connect two tubes with a movable joint that rotates or pivots on a fixed bolt. Once aligned, the clamp tightens to lock the angle in place without shift. Used in angled frames, fold-out rails or site-built bracing, the joint adapts to irregular layouts and changing geometry. Articulated fittings allow pre-load movement during assembly but remain stable under force. Rotation resistance is created by surface pressure at the joint and the angle of compression.

Two-Part and Hinged Couplers

Two-part couplers close around the pipe without needing to slide the tube through. A hinged or split design allows full enclosure using bolts, clamps or latch fasteners. Useful for repairs, retrofits or hard- to-reach pipework, the housing grips the surface from both sides. No disassembly of the structure is required. Internal faces align with tube curvature to prevent rotation or axial shift. Used in upgrades, machinery frames and modular retrofits where access is limited but stability matters.

Applications of Pipe Couplers in Frames and Installations

Pipe couplers define the structure of a steel fence by controlling how tubes connect at fixed positions. The fitting determines whether a rail runs straight, intersects, turns a corner or ends at the ground. In technical fencing systems, each coupler sets the geometry and spacing between rails and uprights. The frame remains aligned under load and allows repeat installation without distortion or drift. Selection depends on tube layout, connection angle and available mounting access. T-joints, cross-joints, base flanges and swivels each serve a distinct role in shaping the fence and transferring force. The examples below show how pipe couplers form the key joints in modular steel fencing and how each type

supports stability, orientation and long-term performance.

Pipe Coupler T-Joint

Connects a horizontal rail to a vertical tube in fixed layouts. Placed at mid-height or top of a fence post to hold rails in line. Used in straight runs or corners where spacing must stay exact. The fitting locks both tubes and keeps the frame aligned during use.

Pipe Coupler Cross-Joint

Links four tubes around a single upright. Used at intersection points in square fencing layouts or grid frames. Holds tubes in position without movement. Applied where rails meet from both sides and symmetry is required. Each direction is clamped separately to maintain shape and load resistance.

Pipe Coupler Base Flange

Mounts an upright tube to the ground using bolts through the base plate. Used at the start or end of a fence, or where a post must stand without digging. Transfers weight and side load into concrete, steel or timber without movement or shifting.

Pipe Coupler Swivel Bracket

Joins two tubes at a set angle. Used on ramps, stairways or uneven ground. The fitting rotates into place and locks after alignment. Keeps angled sections stable under load. Used when the fence must follow a slope or shift in height across the section.

Buisklem - Europe’s Specialist in High-Quality Pipe Couplers

Buisklem supplies steel pipe couplers for structural frames, railings and modular assemblies across Europe. Each part is engineered for precise fit, load transfer and repeat installation without failure. Orders placed before 15:00 are shipped the same day. Stock volumes, small runs and custom production are available on request. Surface treatment protects against corrosion, impact and site exposure. Contractors, manufacturers and distributors rely on Buisklem for durable fittings in high-load construction. Technical support is available in Dutch, English and German. Fast logistics and proven availability keep every project on schedule.