Fence connectors are selected according to the structure, layout and load profile of the fencing system.

Mesh panels require precise alignment between vertical posts and horizontal rails. Tensioned wire

needs secure joints that withstand pulling forces and absorb vibration. In modular or sloped

configurations, multi-way fittings connect frames at changing angles and elevations. T-connectors

secure cross-sections, corner clamps stabilise directional changes, and reinforced models maintain

position under continuous pressure. Each connector type contributes to a stable fence layout that

holds its form across tensioned, rigid and modular assemblies.

Connector Selection for Different Fence Types

A fence defines space in livestock areas, within stables, and around solar parks, sports fields, industrial

zones and public areas. Design choices vary by setting, but performance always depends on how the

frame connects under force. On uneven terrain or in shifting layouts, joints must absorb angle changes

without losing stability. In high-vibration zones or open areas with strong wind, fixed alignment and

bracing are critical. Large-scale projects such as solar parks require fast installation and long-term

mechanical strength without compromise. The joint is not only a link between components but a

structural element that controls how the system behaves. A field enclosure for infrastructure carries

tension across distance. A sports perimeter requires flat alignment and visual order. A perimeter fence

defines the outer boundary of a site and must remain secure over time, even under environmental

stress and external force. In this configuration, the connection must maintain rigidity while preventing

displacement at corner points and transition lines. Where the connector holds position, the fence

retains its shape, load balance and full structural function.

Applications of Barbed Wire Heads and Tube Connectors in Perimeter Fencing

Perimeter fences installed around solar fields, industrial zones and sports grounds are designed to do

more than mark boundaries. The structure must prevent access, absorb pressure and remain stable on

uneven ground and in exposed locations. Aluminium tube frames define the layout and carry the load.

Tensioned wire is held in position by wire tensioners and clamping rings that maintain pressure and

alignment along the fence line. At corners, ends and tension zones, connectors must remain stable and

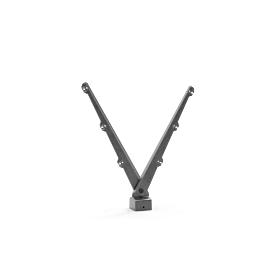

absorb force without displacement. Barbed wire arms extend the protective reach where security is

essential. Mounting brackets distribute weight at key stress points, while base plates and ground rings

provide stable footing on irregular surfaces. Secure boundary systems depend on fixed alignment at

every stress point. When tube connectors, barbed wire fittings and anchoring elements remain stable,

the fence continues to deliver controlled access, load resistance and long-term perimeter reliability.

Specialist Components for Custom-Built Fencing Solutions

Across Europe, perimeter fencing often requires adaptation to suit specific locations, industry

applications and installation regulations. Buisklem supplies modular connectors and brackets that

enable customised layouts without welding or specialised equipment. Systems can be adjusted for

uneven ground, sloped configurations or pressure-specific zoning. Whether installed at a solar site,

livestock enclosure or industrial boundary, each structure can be configured with precise control over

spacing and anchoring. Consistent tube dimensions and dedicated fittings simplify planning across

different terrain types and national standards. Modular components matched to standard tube profiles

enable consistent installation, reliable joint strength and adaptable layouts across sectors.